3D Scanning Services Cost and Pricing Examples

We have extensive experience in all 3D scanning services and related fields which means we are very efficient. Our clients are frequently surprised at how the cost of our 3D scanning services can be so reasonable. Obviously, every project is different, but this page provides the 3D scanning services cost for a variety of types of projects. And if you scroll down, you will see our 3D scanning prices listed for a single part, based on the intended use of the files.

PRODUCT DESIGN and 3D PRINTING

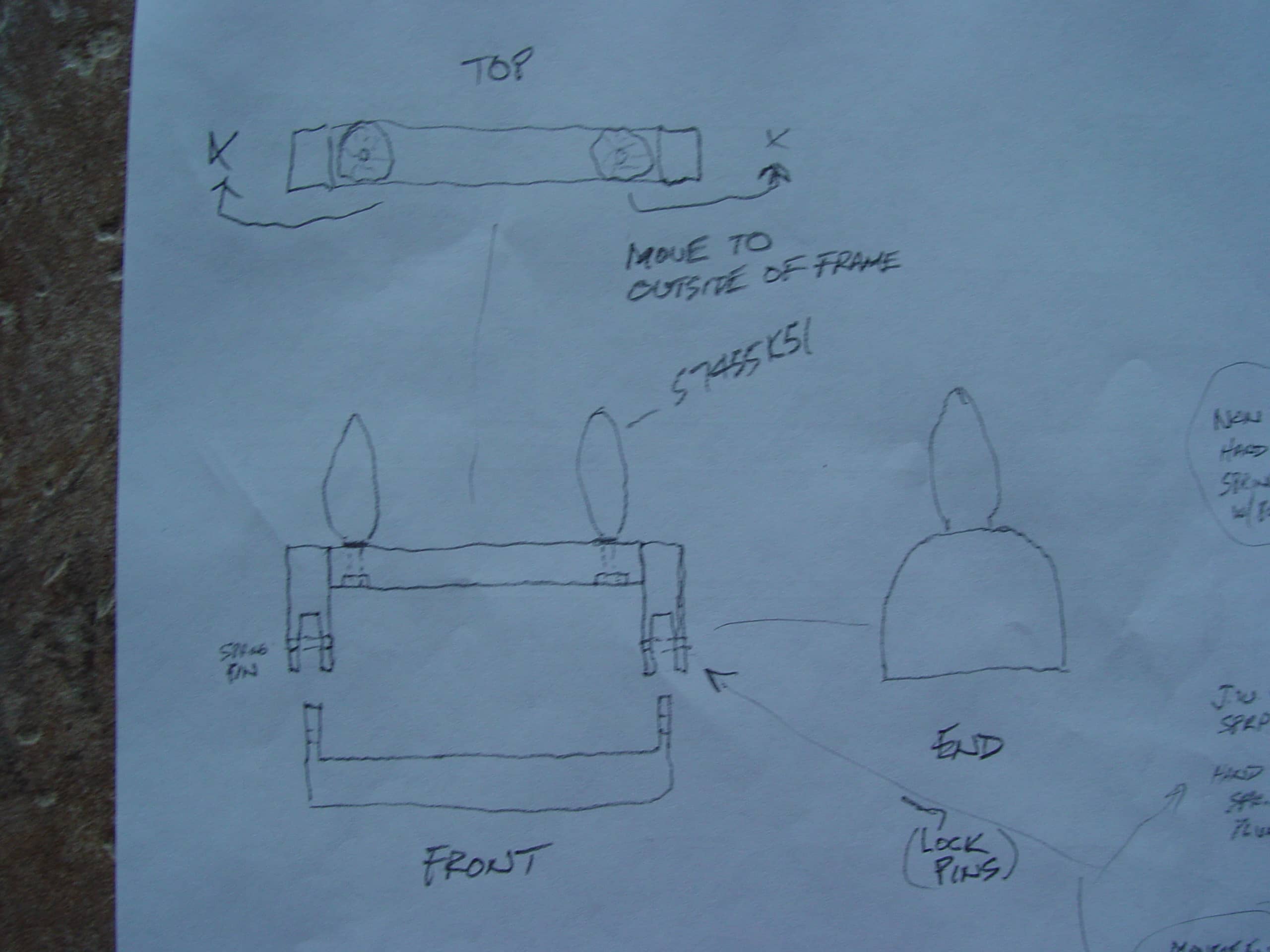

Problem: Only a rough concept sketch available

Needs: 3D model for design edits, and files for 3D printing a prototype

Initial Supplied Sketch

3D Model

File Conversion

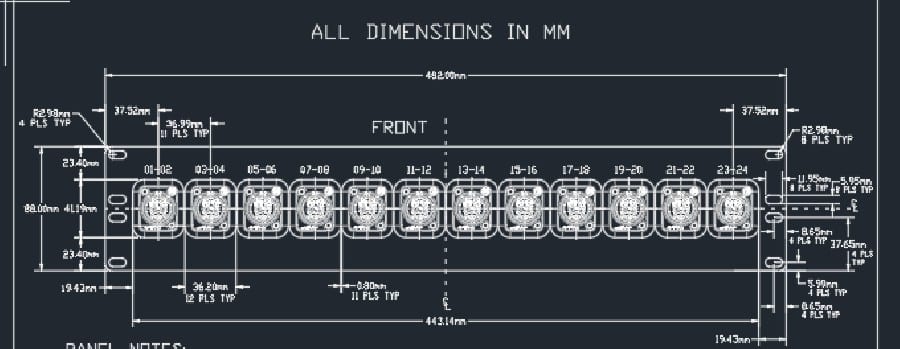

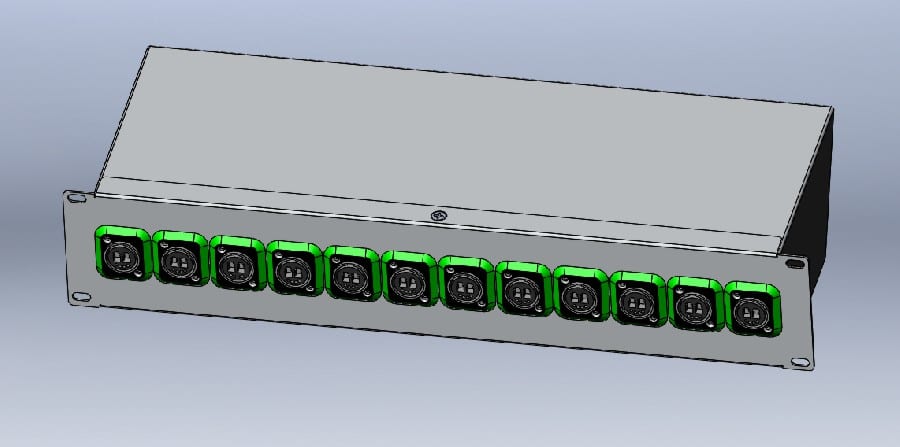

Problem : Only available as a 2D .DWG file.

Needs : 3D model of part

Client Supplied Files

3D Model

Scroll Down Below the Table for More 3D Scanning and Drawing Conversion Example Projects and Prices

Scan Cost Matrix for a Single Part

| Scan Cost | Resolution | Notes | Final Cost |

| $35 to $70 | .1mm | .stl file (mesh) output usually for 3D printing | $120 to $150 |

| $90 to $125 | .05mm | .stp, .igs, or equivalent 3D model, no future edits | $215 to $250 |

| $90 to $125 | .05mm | parametric solid, future edits anticipated and drawings | $285 to $375 |

| $175+ | .009mm | parametric solid, future edits anticipated and drawings | $315 to $425 |

| $228 | .05mm | surfaces created directly from mesh | $500 to $725 |

The above chart shows the cost variation based on resolution and intended file use for identical part scans. The part was a 4” X 4” X 5” mechanical part of moderate complexity. Scan cost refers to raw data, final cost is after editing and clean-up of raw scans.

Typically, increased accuracy and resolution require the scan process to utilize more expensive scan equipment. If mesh data will be used to create direct surface patches, this also increases the cost and amount of editing. Solid models typically can use lower resolution scans, but more time is used to create the parametric model. As you can see, there are trade-offs with every process. The intended use of the output files is one factor in determining which scanner is best for a particular part. Size of the part will also determine which scanner is applicable. The smaller the part, the more costly the scan and editing due to increased accuracy and resolution requirements. Complexity of the geometry also has a large impact, as well as difficulty in capturing clear, very dark, or highly reflective parts.

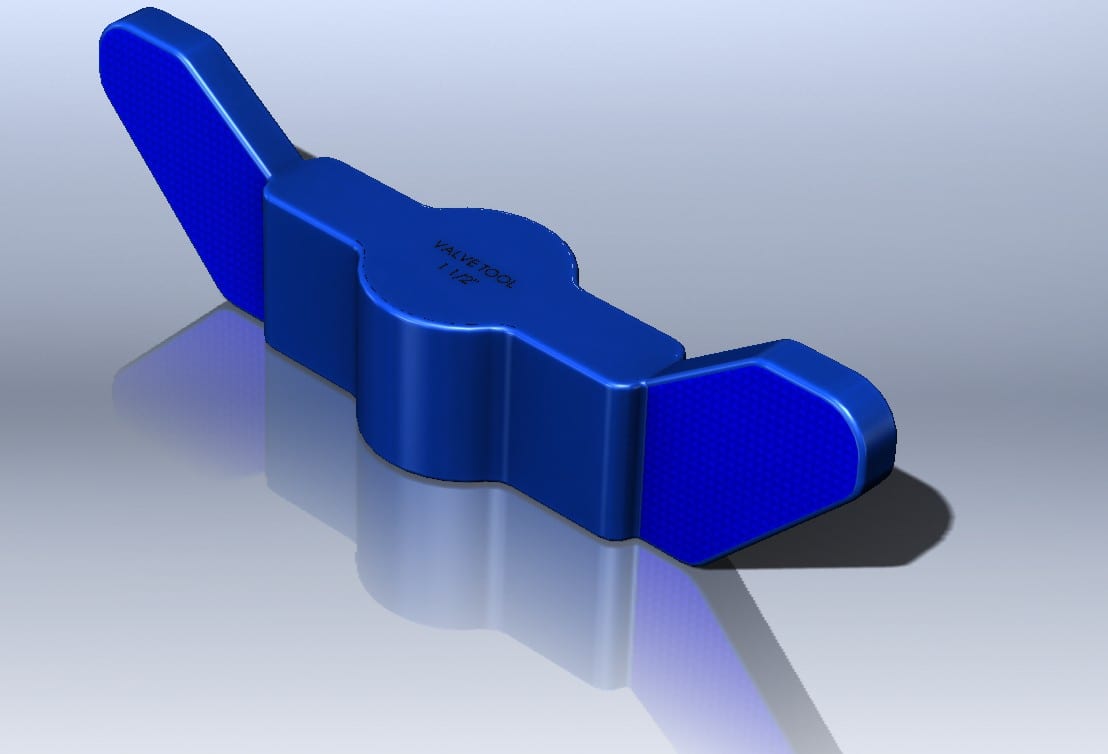

PHOTO-REALISTIC RENDERING

Problem: No images available for marketing or owner’s manual

Needs: Photo-realistic rendering for sales and graphic art departments

CAD Model

Rendered Model

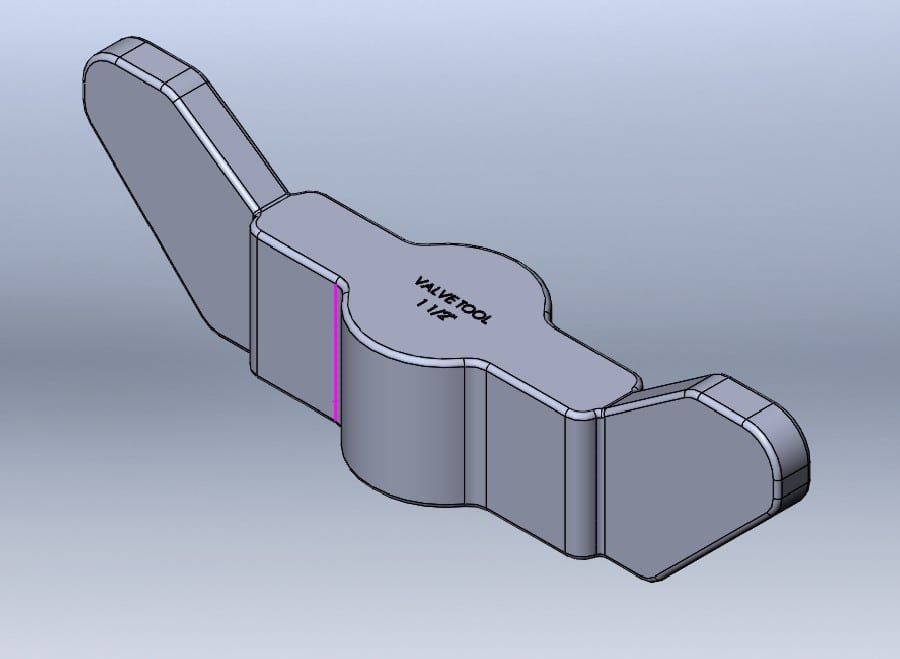

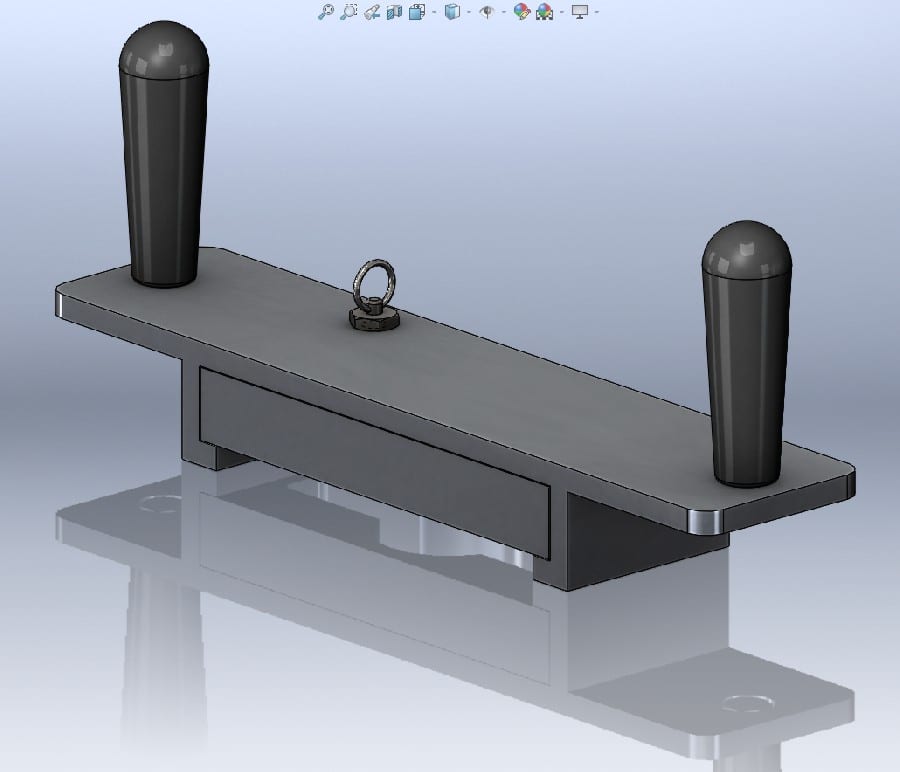

Reverse Engineering

Problem : No CAD files or drawing available for existing part.

Needs : Scan for design change – engineering department needs a fully parametric Solidworks 3D model

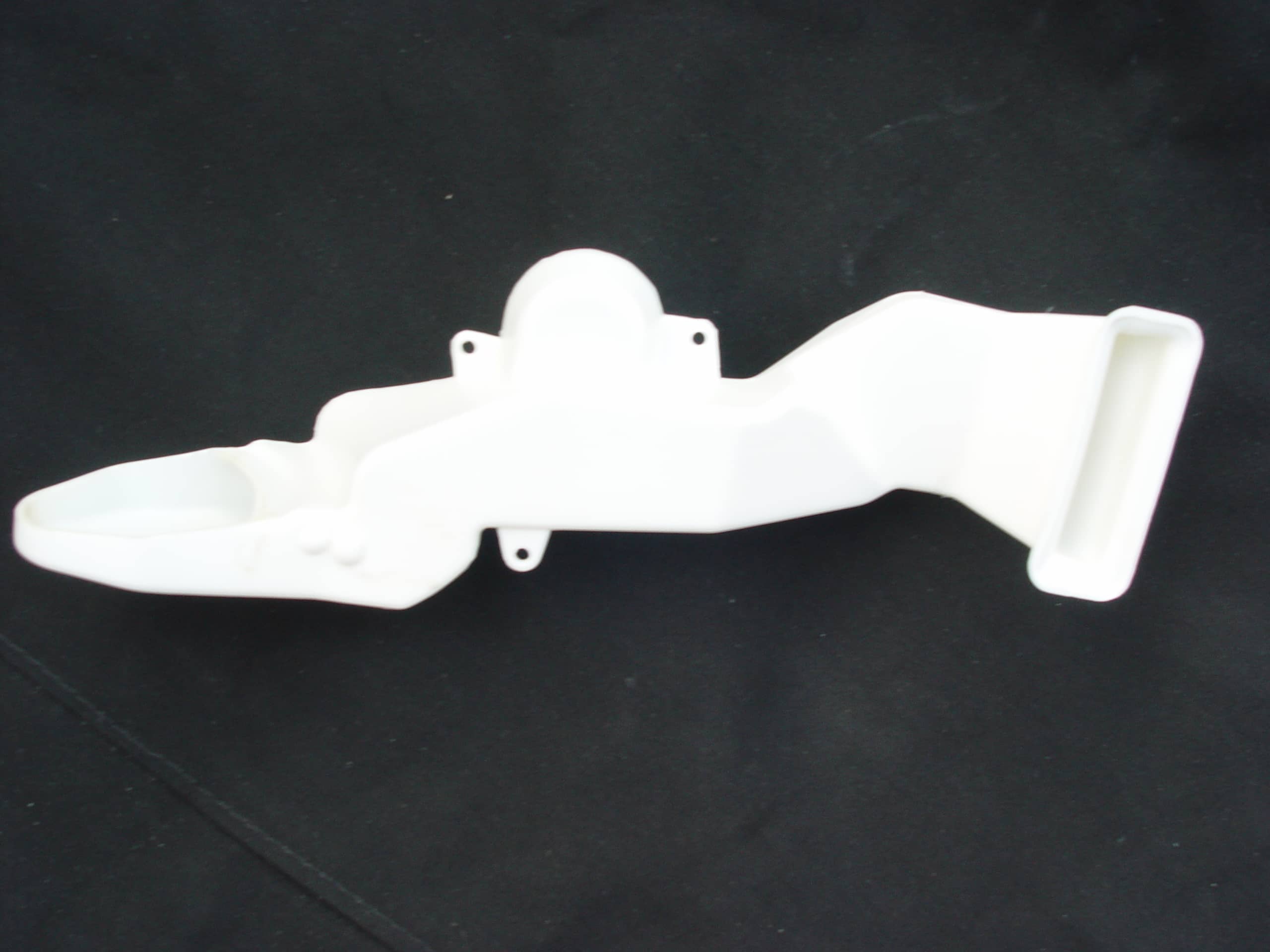

Existing part to scan

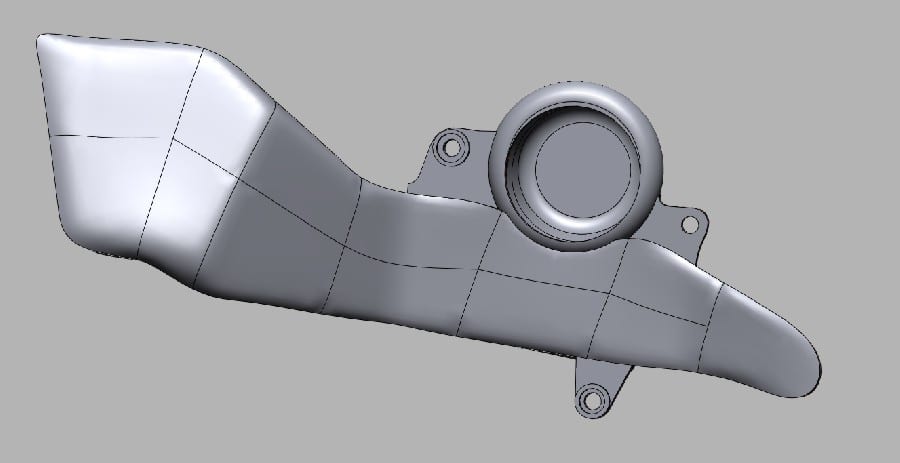

Finished 3D model

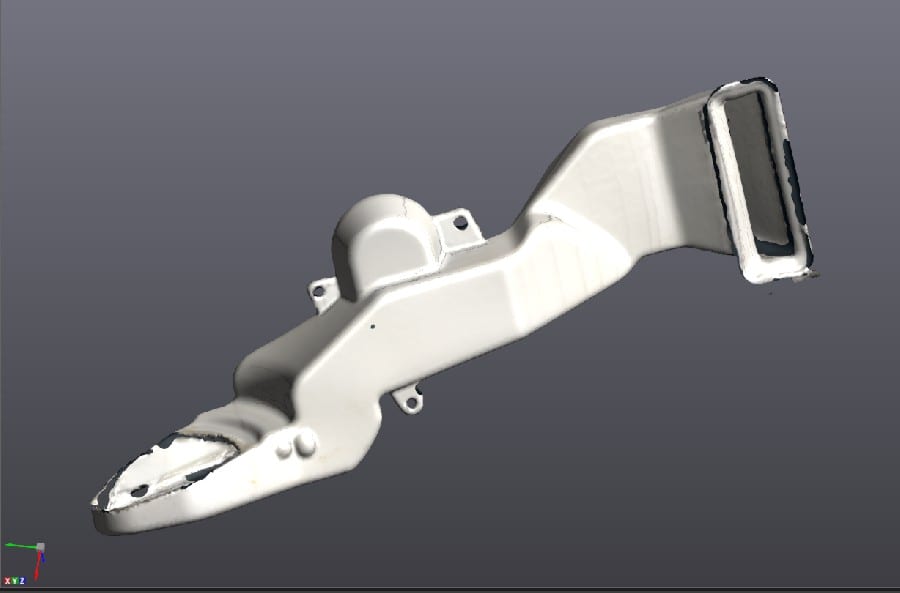

Raw Scan

Molded or Cast Parts

Problem : Complex Geometry – unable to create with traditional CAD

Needs : As-is solid model with color and texture details

Partial 3D scan of Dinosaur

Finished Model

Explore the possibilities